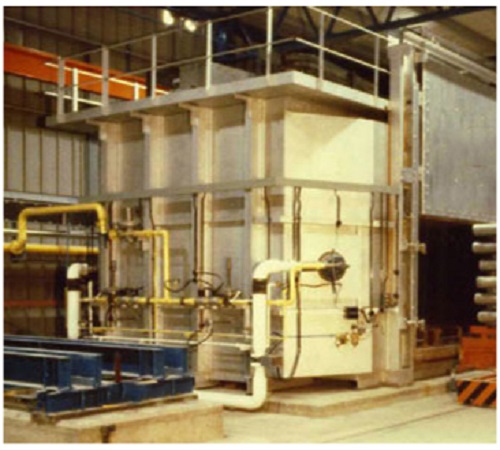

Aluminum Homogenising Furnace

JR FURNACE offers Custom engineered aluminium log and billet homogenizing furnaces for most process applications. With the batch type design, typically an electrically driven insulated bogie is used to move a load into and out of the furnace. Often, a double ended furnace (door at each end) is used with two bogie so turnaround time is reduced, thus maximizing production. The alternative to the car bottom design for the batch type units is the tray design. With this design, the load tray rests on a series of support piers within the furnace. A charge machine/transfer car is used for charging/discharging of the tray and transferring the tray from the furnace to a cooling station or to a load/unload station. A third type of batch unit is the travelling furnace.

This furnace uses a pair of fixed load bases to support the load. When the cycle is completed on base No. 1, the furnace moves into position over the second load base and immediately begins heating a new load. The previous load is allowed to cool, then is unloaded and replaced with a new load. This can all be accomplished before the next homogenizing cycle is completed. A travelling furnace provides savings in floor because the two load bases require significantly less floor space compared with a double-ended stationery furnace with two load cars.

JR FURNACE reversing airflow design with upstream/downstream temperature control using an axial flow fan wheel reverses rotation on a timed basis, which, in turn, reverses the direction of the horizontal airflow through the load. The air stream temperature is monitored and controlled on each side of the load. A thermal head is used during the early stages of the cycle for fast, efficient heating. This design increases both the heating rate and temperature uniformity of the load compared with one-way airflow, resulting in better efficiency, lower fuel cost, and improved metallurgical results.

JRFURNACE holds the patent on the adjustable airflow baffle. These movable baffles greatly increase furnace performance, especially when less than the maximum size loads are being homogenized. The baffles are adjustable according to the height of the load to effectively limit or block the open space that exists above the load. / Shorter heat up rates due to increased airflow velocity / Preventing short circuiting of the airflow when less than the maximum size load is homogenized / Preventing overheating of the top layer / Lower energy requirements since faster heat-up rates are achieved / Increased uniformity since the airflow is channelled more evenly across all load surfaces.

Cooling after homogenization can add significant value to the logs or billets. Production requirements are requiring faster, more uniform cooling of the logs or billets. Evidence increasingly shows that the resulting grain structure and workability properties of the billets are a result of the cooling medium to use after homogenization. While fast cooling is desirable, it must also be uniform throughout the load space or significant bowing of the logs could occur. For batch type loads using a car or tray, JRFURNACE offers a variety of load cooler designs such as one-way airflow, reversing airflow, air/mist arrangements, etc., depending on the level of performance required. These chambers are designed to cool the load uniformly to your specifications. The cooling rate can also be controlled using variable speed cooling fans.

- Features & Specifications

- Temperature Range – Upto 1100°C

- From 50 to 1500 KW

- Batch capacity upto 200 MT.

- Insulation – Vacuum Formed Ceramic Fibre Boards / Ceramic Fibre Blanket & Module / Brick Lining

- Heating Media Options – Electric / Gas Fired / Oil Fired

- Heating Elements – Nichrome Wire /Strip Wire

- Sealing of the vertical lift doors and bogie through pneumatically operated soft seal clamps to ensure no ingress of cold air.

- Furnace Classification – Class 2 / Class 3

- Instrumentation – Thyristor, Programmable Temperature Controller, Temperature Recorder, PLC, SCADA, HMI

- Applications

Homogenizing of Aluminium and Billets