Pit Furnaces | Gas Carburizing Furnace

JR FURNACE has a full range of Pit type Heat Treatment up to a capacity of 100 MT for hardening, annealing, normalizing, carburizing, nitriding, tempering, aging and stress relieving to offer to industries like Fastener, Bearing, Forge Parts, Gears, Rolls, Strip, Wire, Piston rings etc in steel industries besides cylinder heads and pistons for Aluminium industries.

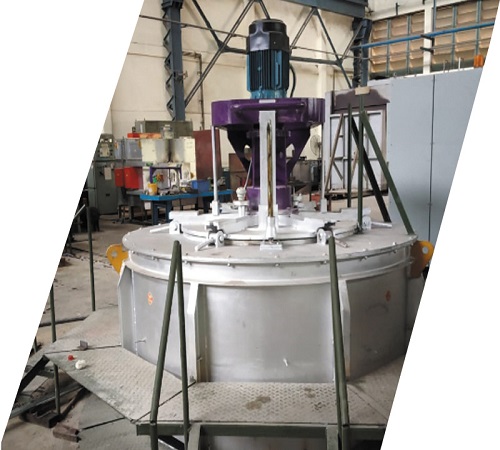

JR Furnace & Ovens – Offering Gas carburising furnace is basically pot-pit type furnace used for hardening case carburising carbonitriding of various components made of steel such as construction machinery parts, precision turned components, gears, auto parts etc.

These Gas carburising furnaces are of circular construction with insulated cover which is hydraulically lifted/swivelled for charging or discharging the material into and from the furnace.

The charge material can be loaded into the Pit furnace with the help of EOT crane or suitable loading machine. The Pit furnaces can also be offered with quenching facilities and washing machine to suit customers’ requirements.

Pit furnaces are offered with or without sealed retorts for inert/reducing atmosphere or normal oxidizing atmosphere applications.

The furnaces with inert/reducing atmosphere applications will have facility for introducing atmosphere like hydro-carbon rich gas, ammonia and nitrogen into a sealed retort made of stainless steel of AISI-310/304 depending on the application temperature. The lid is fitted with gas tight through water-cooled neoprene/silicon rubber seal for proper sealing.

These Gas carburising furnaces can be either electrically heated or fuel fired. The electrically heated furnaces are provided with resistive strip/wire heating elements located on the sidewall of the furnace.

The heating elements of the furnace are suitably divided into number of heating zones and can be controlled through contactor or thyristor based control philosophy through PID controllers.

Fuel fired Pit furnaces are offered with high efficiency burners for Oil/Gas application supported by a full complement of combustion control system with safety devices.

Hot air circulation inside the furnace is made by efficient centrifugal or axial type recirculation fan which can be with two speed motor or with VFD drive.

Pit furnaces are lined with ceramic fibre block/module at side wall and lid cover. Bottom hearth will be lined with refractory bricks backed by insulation bricks, specially designed to withstand load to minimize the skin temperature.

JR FURNACE has full capability to offer complete control and instrumentation system through PLC based or Hardware based logic controls.

- Features & Specifications

- Batch capacity up to 2 MT.

- Maximum temperature up to 1000 ˚C.

- Temperature uniformity within +/- 5 ˚C.

- Leak tight retort and door assembly.

- Powerful fan for gas circulation.

- Vacuum assistance for annealing and normalizing.

- Carbon potential control

- Heating Media Options – Electric / Gas Fired / Oil Fired

- Heating Elements – Nichrome Wire /Strip Wire

- Furnace Classification – Class 2 / Class 3

- Instrumentation – Thyristor, Programmable Temperature Controller, Temperature Recorder, PLC, SCADA, HMI.

- Applications

- Annealing/Annealing under protective atmosphere

- Isothermal Annealing

- Carbonitriding

- Carburizing

- Decarb annealing

- Gas Nitriding

- Hardening

- Stress Relieving

- Wire annealing

- Ferritic Nitro Carburizing

- Normalizing

- Case Hardening

Frequently Asked Auestion

(FAQ)

How to operate the Door?

Hydraulically operated lifting and swivelling type Door is provided to move away the door from furnace top for loading and unloading of charge materials by EOT crane/ purchaser’s means. The lifting/lowering arrangement is provided with self standing structural mounted independently on floor having its arms attached to door.

What is the function of recirculation fan?

In order to enhance the convection heat transfer and temperature uniformity one axial flow type re-circulating fan is provided. The fan is located centrally on the lid cover of the furnace. The fan impeller and shaft will be made of AISI-310. The fan is having insulated plug and assembled to facilitate removal as a complete unit.

Also Check Our Other Batch Type Furnaces

- Sealed Quench Furnace

- Drop Bottom Quench Furnace

- Salt Bath Furnace

- Bell Furnace

- Gas Nitriding Furnace

- Grooved Hearth Type Furnace

- Aluminium Melting Furnace

- Rotary Hearth Furnace

- Tempering Furnace