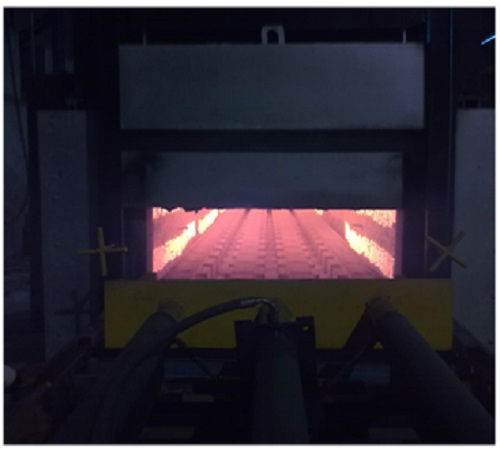

Pusher Type Furnace

Pusher Furnaces are manufactured by JR Furnace are fully automatic and incorporate several innovative and unique features and are designed offering maximum flexibility, high reproducibility, lower energy costs and greater uptime, and can be customized to meet your exact heat treatment and processing requirements.

- Application

Normally, Pusher Furnaces are used for thermo-chemical heat treatment of parts suited for high volumes and less product variety and mix to carry out operations like carburizing and hardening, Annealing, Stress Relieving, Solution Treating and Ageing and the wide parts spectrum which can be processed covers Automotive Components of all kinds, mostly Transmission and Axle components. Gear Components, Shafts, Castings, Drive train components, forgings and engine components etc.

- Features:

- Ability to handle variable production rates and simultaneously process large number of different parts.

- Pusher furnaces are always tailor made and designed depending on the production requirement, type of components and type of process required, space availability etc.

- Heating System can be Electrically heated type or Gas Fired type

- Gas used for heating and process can be LPG/Propane/Natural Gas.

- Available with Free and/or Press quenching Capabilities.

- Available in a variety of control platform providing totally automatic operation with controlling, tracking, data monitoring and acquisition capability.

- Furnace atmosphere possible:

- With Endogas and LPG/Propane/Natural gas

- With Methanol + Nitrogen and LPG/Propane/Natural gas.

- Compact, Robust, Fail-Safe & Space Saving Design with state-of-the-art technology.

- Recirculation and not agitation leads to uniform distribution of temperature and protective atmosphere leading to best in class repeatability.

- Single and Multi row as well as single and multi chamber design available offering high flexibility.

- Furnace shell equipped with light weight and low heat retaining insulation and provided with silicon carbide segmented skids on hearth minimizing heat loss and low skin temperature.

- All Pusher mechanisms dedicated for heavy loads.

- Advanced temperature and carbon potential Control System leading to Fully automatic control system with interface for modern process control systems

- Can be designed with floor mounted quenching oil and washing machine tanks eliminating costly civil work for pits.

- High operational safety and easy to operate and maintain.

- Advantages

- Our Pusher Furnaces have Ability to handle variable production rates and simultaneously process large number of different parts.

- Compact, Robust, Fail-Safe & Space Saving Design with state-of-the-art technology.

- Recirculation and not agitation leads to uniform distribution of temperature and protective atmosphere leading to best in class repeatability.

- Single and Multi row as well as single and multi chamber design available offering high flexibility.

- Furnace shell equipped with light weight and low heat retaining insulation and provided with silicon carbide segmented skids on hearth minimizing heat loss and low skin temperature.

- All Pusher mechanisms dedicated for heavy loads.

- Advanced temperature and carbon potential Control System leading to Fully automatic control system with interface for modern process control systems

- Can be designed with floor mounted quenching oil and washing machine tanks eliminating costly civil work for pits.

- High operational safety and easy to operate and maintain.