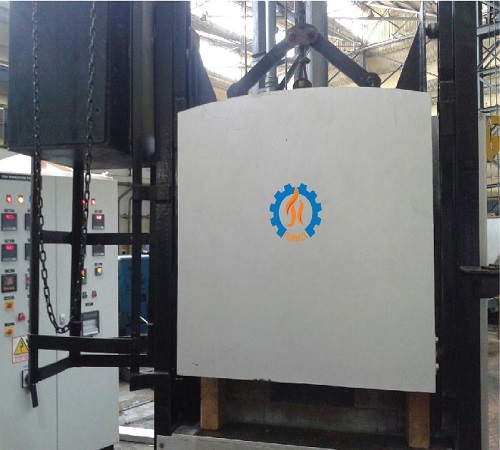

Chamber Type Forging Furnace

JRFURNACE has built a large number of fuel fired and electrically heated Chamber furnaces & Forging Furnace for reheating and heat treatment applications in past two decades. JRFURNACE has a full range of Chamber type Reheating and Heat Treatment Furnaces to offer to Steel Mills, Heavy Structurals, Forgings, Foundry Cast House, and other metal industries with temperature range of 2000C to 13500C. These Chamber Type Forging Furnace can be offered with vertical rise and fall type doors with electro-mechanical drive system. The materials are loaded on the hearth of the chamber furnace with the help of manipulator/robot or manually with tongs depending on the size and weight of the material. After reheating/heat treatment operation, the material can be unloaded with the help of above machines. Chamber Type Forging Furnace can also be offered with grooved hearth construction suitable for loading/unloading of material with the help of fork type hydraulically or electro-mechanically operated machine.

The furnace can be provided with electrical heating through heat resistant Strip/Wire/rod type heating elements located along with the side/back walls/roof of the furnace. The heating elements of the furnace are suitably divided into number of heating zones with each zone of having their bank of heater. The heating elements of the furnace are suitably divided into number of heating zones and can be controlled through Contactor or Thyristor based control philosophy through PID controllers.

JRFURNACE Chamber Type Forging Furnace are lined with ceramic fiber modules/blankets or dense firebricks backed by insulation bricks on the side wall, roof and door and hearth of the furnace will be provided with combination of high/medium grade aluminum bricks backed-up by insulation bricks to minimize the skin temperature.

The Preheating Furnace are heated either with natural gas or electrically, depending on the clients requirements. JR Furnace offers one of the most comprehensive heat treatment furnace and Preheating Furnace lines on the market.

- Power Source: Electric

- Automation Grade: Automatic

- Max Temperature: 1300 degree Celsius

- Features & Specifications

- Temperature Range Up to 1500°C

- Door Design Hinge Type/Vertical Lifting

- Insulation Vacuum Formed Ceramic Fibre Boards/Ceramic Fibre Blanket & Module/Refractory Brick Lining

- Heating Elements Nichrome Wire/Special Alloy Resistance Heating Wire/Silicon Carbide/Molybdenum Di-Silicide/Molybdenum Wire

- Instrumentation options Thyristor, Programmable Temperature Controller, Temperature Recorder, PLC, SCADA, HMI

- Applications

- Hardening

- Tempering

- Annealing / Annealing under protective atmosphere

- Isothermal Annealing

- Post Weld Heat Treatment

- Stress relieving

- Wire Annealing

- Normalizing

- Carburizing

- Case Hardening

- Carbonitriding

- Decarb Annealing

- Ferritic Nitro Carburizing

- Blueing

- Austempering / Bainitic hardening

- Austenitizing