Industrial Ovens Manufacturer in India

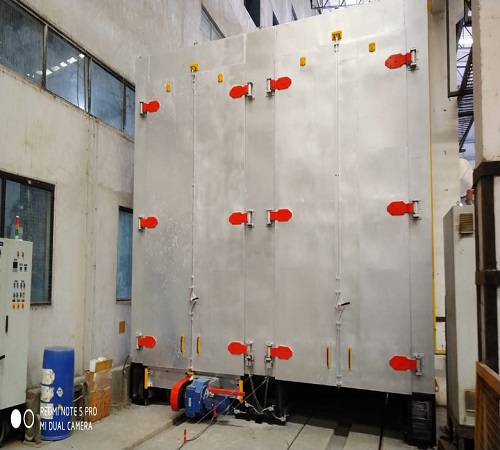

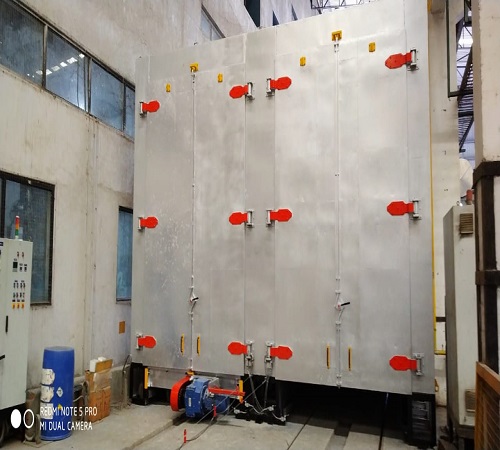

JR FURNACE offers different type of industrial ovens ovens like Bogie Type Ovens, Composite Curing Ovens, Curing Ovens, Drying Ovens, Core Drying Ovens, Preheat Ovens, Annealing Ovens, Ageing Ovens, Conveyor Ovens, Hydrogen Embrittlement Ovens, Tempering Ovens, Paint Baking Ovens and Powder Coating Ovens.

JR FURNACE has supplied a more number of Electrically heated and Fuel fired Bogie/Batch/Continuous ovens for the past two decades.

As a Leading Industrial Ovens Manufacturer in India has a full range of Bogie/Batch/Continuous industrial ovens up-to a capacity of 200 MT to offer to Foundry Cast House, Heavy Engineering, Automobile, Rail Wagon, Electrical Machines and other metal industries with temperature range of 50°C to 450°C.

JR FURNACE manufactures standard batch and continuous ovens in a variety of sizes. Standard ovens are an excellent choice and offer industrial proven, tested performance, fast delivery and at a reduced price compared to a custom engineered machine.

In electrically heated industrial ovens with electrical heating system through resistive Cartridge type/Tubular type heating elements located along with the side/back walls/roof of the oven. In fuel fired ovens are fired with high efficiency burners supported by a full complement of combustion system with safety arrangements.

Custom ovens are tailored to your specific worksite and requirements. To meet process and safety requirements, the exhaust system is engineered to accommodate specific moisture release rates. Multiple heat zone configurations can be provided to maximize drying efficiency. Industrial Ovens can be used for a wide variety of heat processes including drying, curing, aging, annealing, stress relieving, bonding, tempering, preheating and forming.

- Features & Specifications

- Rigid and strong construction to withstand operational stress

- Temperature upto 450°C

- In housed Manufactured Tubular Heaters

- Direct or Indirect Firing

- Heating Media Options – Electric / Fuel Fired

- High Quality Energy saving insulation

- Powerful airflow for optimum uniformity

- Exhaust damper helps in ventilating and faster cooling of chamber.

- Control panel complies IP65 standard

- User-friendly, full-automated PLC based SCADA system with HMI interface

- APPLICATION

- Aerospace/Composites Automotive Electric Motor & Transformers Foundry Heat Treating

- Aluminium Ageing

- Heat-Treating

- Curing Coatings

- Curing Resins and Epoxies

- Drying

- Preheating

- Annealing

- Shrink-Fitting and Shrink packing/wrapping

- Powder Coating

- Stress Reliving

- Tempering

- Baking

- Die heating