Heat Treatment Furnace Manufacturers in South Africa

Welcome to the premier source for Heat Treatment Furnace Manufacturers in South Africa!

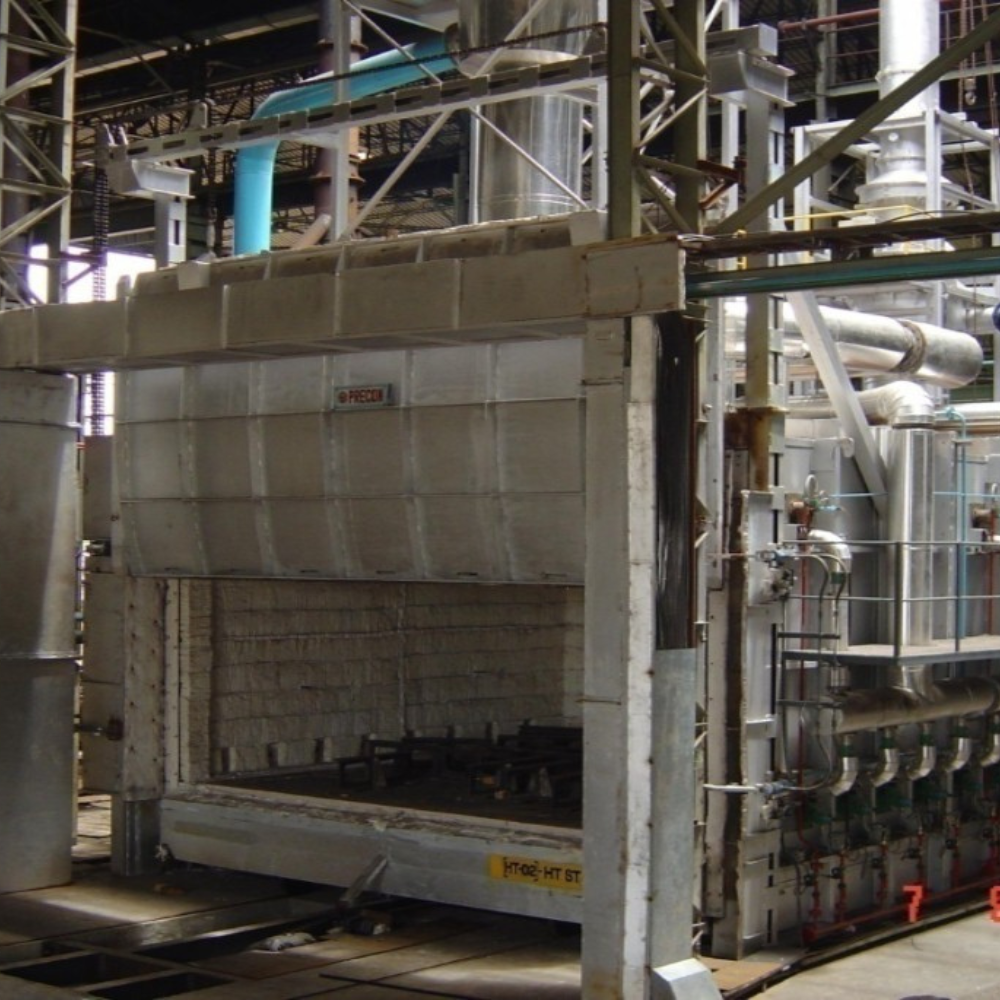

Looking for a reliable and specialized Heat Treatment Furnace manufacturer? Look no further than JR Furnace. Our company is an ISO 9001:2015 certified manufacturer of all types of heat treatment furnaces, known for their heavy-duty construction, uniformity, cost-effectiveness, and low maintenance needs. With over 35 years of experience and more than 500 satisfied clients worldwide, we pride ourselves on our cutting-edge technology and robust structures.

Our heat treatment furnaces are designed to meet AMS 2750, NADCAP, and Pyrometry standards and are suitable for various industries such as Aerospace, Cable/Conductor industries, Renewable Energy industries, Steel Foundry /Forging /Investment casting and Aluminium Extrusion, Aluminium Process foundry industry, Defence, Railways and Power sector.

Our product line includes Ageing Furnace, Quenching Furnace, Solutionising Furnace, Gas Carburizing Furnace, Tempering Furnace, Annealing Furnace, Stress Relieving Furnace, Hardening Furnace, Salt Bath Furnace, Sealed Quench Furnace, Bell Furnace, Postweld heat treatment furnace, and Normalizing Furnace. Our furnaces are programmed and controlled through a standard PLC/SCADA system and all temperature and recording instruments, thermocouple will be calibrated by NABL or equivalent standard.

Our team of experienced engineers ensure that all safety interlocks are designed in furnace and also carry out temperature uniformity survey for at least 2-3 cycles after installation. Our furnace can be used for various applications such as brazing of various steel alloys and titanium alloy base parts, heating of billets, hardening & tempering of steel, solutionizing heat treatment of aluminum alloy parts, aging heat treatment on aluminum alloy parts, carburizing & carbo-nitriding, and annealing of low carbon and medium carbon steel tubes.

- Features & Specifications

- Customized Heat Treatment solution

- Temperature Range – Upto 1400°C

- Batch capacity upto 200 MT.

- Heating media- Electric/Gas/Oil fired

- High density energy Insulation – Vacuum Formed Ceramic Fibre Boards / Ceramic Fibre Blanket & Module / Brick Lining

- Fastest heat-up & recovery rates

- Heavy duty and Robust construction

- Furnace Classification – Class 2 / Class

- Thermal calibration as per API standards

- User-friendly, full-automated PLC based SCADA system with HMI interface

- Meets NADCAP, CQI-9 NORMS, AMS2750 STANDARDS

- Pneumatic clamping system for sealing and to avoid heat loss.

- Hydraulic / Pneumatic hoist systems for heavy loads

- Special temperature uniformities from +\- 3 Deg C to above.

- 24/7 factory direct technical service and spare parts group.

- Access through Mobile Network

- Factory tested to ensure on time delivery and field start up.

- Highest energy efficient Gearboxes with inbuilt break system

Why Choose JR Furnace – Heat Treatment Furnace Manufacturers in South Africa

- After sales services like installation, maintenance, training and other support services

- Experience and expertise in the industry

- A wide range of high-quality products

- Competitive prices

- Excellent customer service

- A commitment to providing solutions that meet the specific needs of each customer

Our heat treatment furnace will not only help you achieve the desired properties of the material but also improve the efficiency and productivity of your operations. Browse our website to learn more about our products and services and do not hesitate to contact us for more information or to schedule a consultation.

Thank you for choosing JR. Furnace as your partner in heat treatment solutions.

Send Inquiry