Pit Furnace Manufacturers in Indonesia

Welcome to the premier source for Pit Furnace Manufacturers in Indonesia!

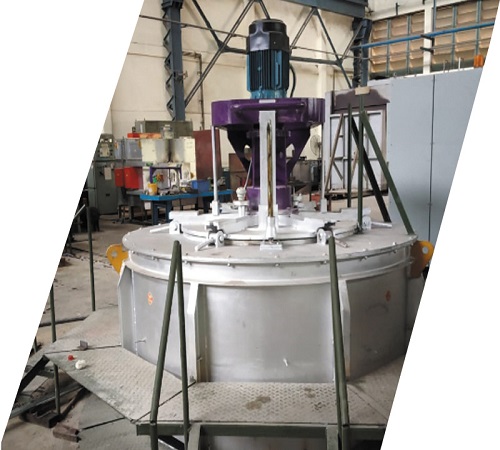

Introducing JR Furnace’s state-of-the-art Pit Furnaces, designed and manufactured to meet the specific needs of industries in Indonesia. Our Pit Furnaces are ideal for solution treatment, tempering, and heating of any densely packed load carried in a cylindrical basket.

Our Pit Furnaces are available in both electric and gas-fired options, suitable for basket diameters up to 48 inches and maximum temperature ratings of 1,400°F. They are constructed with 6 inches of insulation sandwiched between a heavy gauge stainless steel liner (stainless steel at 1,250°F and above) and a heavy gauge plate steel exterior. The furnace utilizes high-pressure recirculation blowers to force heated air through the load in a vertical, top-down arrangement, which provides much faster heating than most other conventional furnace designs.

The Pit Furnace design is space-efficient and easy to use, saving valuable floor space in comparison to horizontally loaded equipment, which requires space for the swing of the doors and for loading/unloading. It also provides easy loading because the door lifts up and swings completely away from the loading area to avoid damage. The door is available in either manual or air-operated designs.

- Features & Specifications

- Batch capacity up to 2 MT.

- Maximum temperature up to 1000 ˚C.

- Temperature uniformity within +/- 5 ˚C.

- Gas-fired or electrically heated

- High-pressure recirculation blower

- Vertical, top-down airflow design

- Heavy-duty construction utilizing 6” or 8″ insulation

- Heating Media Options – Electric / Gas Fired / Oil Fired

- Heating Elements – Nichrome Wire /Strip Wire

- Furnace Classification – Class 2 / Class 3

- Instrumentation – Thyristor, Programmable Temperature Controller, Temperature Recorder, PLC, SCADA, HMI.

- Applications

- Annealing/Annealing under protective atmosphere

- Isothermal Annealing

- Carbonitriding

- Carburizing

- Decarb annealing

- Gas Nitriding

- Hardening

- Stress Relieving

- Wire annealing

- Ferritic Nitro Carburizing

- Normalizing

- Case Hardening

Why Choose JR Furnace – Pit Furnace Manufacturers in Indonesia

- After sales services like installation, maintenance, training and other support services

- Experience and expertise in the industry

- A wide range of high-quality products

- Competitive prices

- Excellent customer service

- A commitment to providing solutions that meet the specific needs of each customer

Frequently Asked Auestion

(FAQ)

How to operate the Door?

Hydraulically operated lifting and swivelling type Door is provided to move away the door from furnace top for loading and unloading of charge materials by EOT crane/ purchaser’s means. The lifting/lowering arrangement is provided with self standing structural mounted independently on floor having its arms attached to door.

What is the function of recirculation fan?

In order to enhance the convection heat transfer and temperature uniformity one axial flow type re-circulating fan is provided. The fan is located centrally on the lid cover of the furnace. The fan impeller and shaft will be made of AISI-310. The fan is having insulated plug and assembled to facilitate removal as a complete unit.