Pit Furnace Manufacturers in Sudan

Welcome to our Pit Furnace manufacturers in Sudan, we specialize in providing high-quality and reliable pit furnaces that are designed to meet the needs of various industries. Our pit furnace is suitable for heat treatment processes such as hardening, tempering, annealing, and normalizing. They are widely used for batch or intermittent processes and are ideal for heat treatment of large and heavy parts such as gears, crankshafts, and other automotive components.

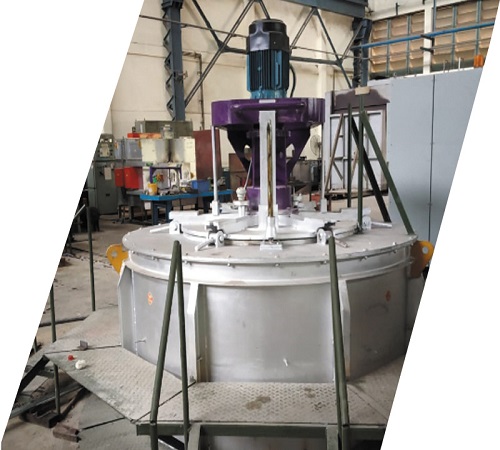

Our pit furnace features a rectangular or cylindrical form and can be single or multi-stack, gas or electric-heated options. The furnace is designed with a pit that is dug into the ground and lined with refractory materials. This allows the furnace to be heated from below, providing an efficient and even heating process. The furnace is equipped with an overhead crane that allows for easy loading and unloading of parts.

At our company, we understand that every customer has unique needs, which is why we offer different pit lifting methods that can be customized to meet your requirements. Additionally, our pit furnace has low maintenance requirements as they don’t have any mechanisms or moving parts inside the furnace, maintenance is limited to the combustion and control equipment.

We are committed to providing our customers in Sudan with the best quality products and services. Our team of experts is dedicated to ensuring that every furnace we manufacture meets the highest standards of quality and performance. Contact us today to learn more about how we can help you with your heat treatment needs in Sudan.

- Features & Specifications

- Batch capacity up to 2 MT.

- Maximum temperature up to 1000 ˚C.

- Temperature uniformity within +/- 5 ˚C.

- Leak tight retort and door assembly.

- Powerful fan for gas circulation.

- Vacuum assistance for annealing and normalizing.

- Carbon potential control

- Heating Media Options – Electric / Gas Fired / Oil Fired

- Heating Elements – Nichrome Wire /Strip Wire

- Furnace Classification – Class 2 / Class 3

- Instrumentation – Thyristor, Programmable Temperature Controller, Temperature Recorder, PLC, SCADA, HMI.

- Applications

- Annealing/Annealing under protective atmosphere

- Isothermal Annealing

- Carbonitriding

- Carburizing

- Decarb annealing

- Gas Nitriding

- Hardening

- Stress Relieving

- Wire annealing

- Ferritic Nitro Carburizing

- Normalizing

- Case Hardening

Why Choose JR Furnace – Pit Furnace Manufacturers in Sudan

- After sales services like installation, maintenance, training and other support services

- Experience and expertise in the industry

- A wide range of high-quality products

- Competitive prices

- Excellent customer service

- A commitment to providing solutions that meet the specific needs of each customer

Frequently Asked Auestion

(FAQ)

How to operate the Door?

Hydraulically operated lifting and swivelling type Door is provided to move away the door from furnace top for loading and unloading of charge materials by EOT crane/ purchaser’s means. The lifting/lowering arrangement is provided with self standing structural mounted independently on floor having its arms attached to door.

What is the function of recirculation fan?

In order to enhance the convection heat transfer and temperature uniformity one axial flow type re-circulating fan is provided. The fan is located centrally on the lid cover of the furnace. The fan impeller and shaft will be made of AISI-310. The fan is having insulated plug and assembled to facilitate removal as a complete unit.