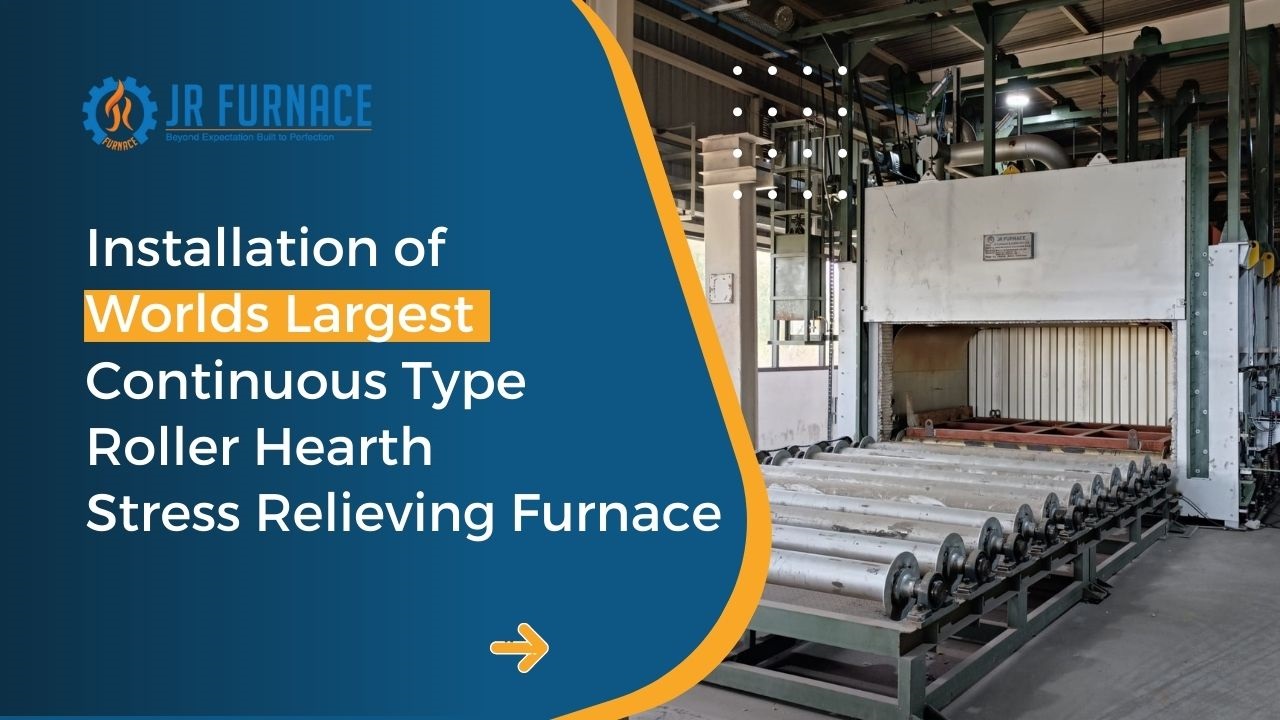

Continuous Type Roller Hearth Stress Relieving Furnace

We have supplied Continuous Type Roller Hearth Furnace with VFD Drive System for Stress Relieving of charge materials like Boom & Dipper to UK based earthmoving and construction equipment company. JR Furnace is the leading manufacturer of continuous type roller hearth furnace which is a superb quality product.

Boom & Dipper will be grouped in Pallets & sent to Continuous Furnace for Stress Relieve Process. It consists of 12 compartments includes heating, soaking and cooling zones. We have proved out the uniformity of +/-5 Deg C.

The output capacity will be 96 boom and dipper per day. The Heating and Cooling Cycles are programmed through the SCADA System.

The furnace is fully automated through PLC and SCADA system The furnace operation and its current parameter will be viewed in mobile / laptop globally through EPLC. The entire system length will be 73 Mtrs.

Highlights:

- Heavy duty construction

- Earth leak protection provided in heater circuit

- Plug in type Fan and its rotation & speed can be accessed through PLC

- Rollers have anti-slippery design for proper movement of pallets

- Rollers will be accessible from one side for maintenance activities

- Provided Pallet Sensing Sensor

- 3-Tier Patlite system with buzzer alarm

- Co2 -Flooding Fire Protection

- Inbuilt LOTO for maintenance activities

- Furnace Temperature Calibration Testing with TTR

- Online Mobile App for Furnace

- SAP integration with PLC

- EPLC with SCADA and HMI