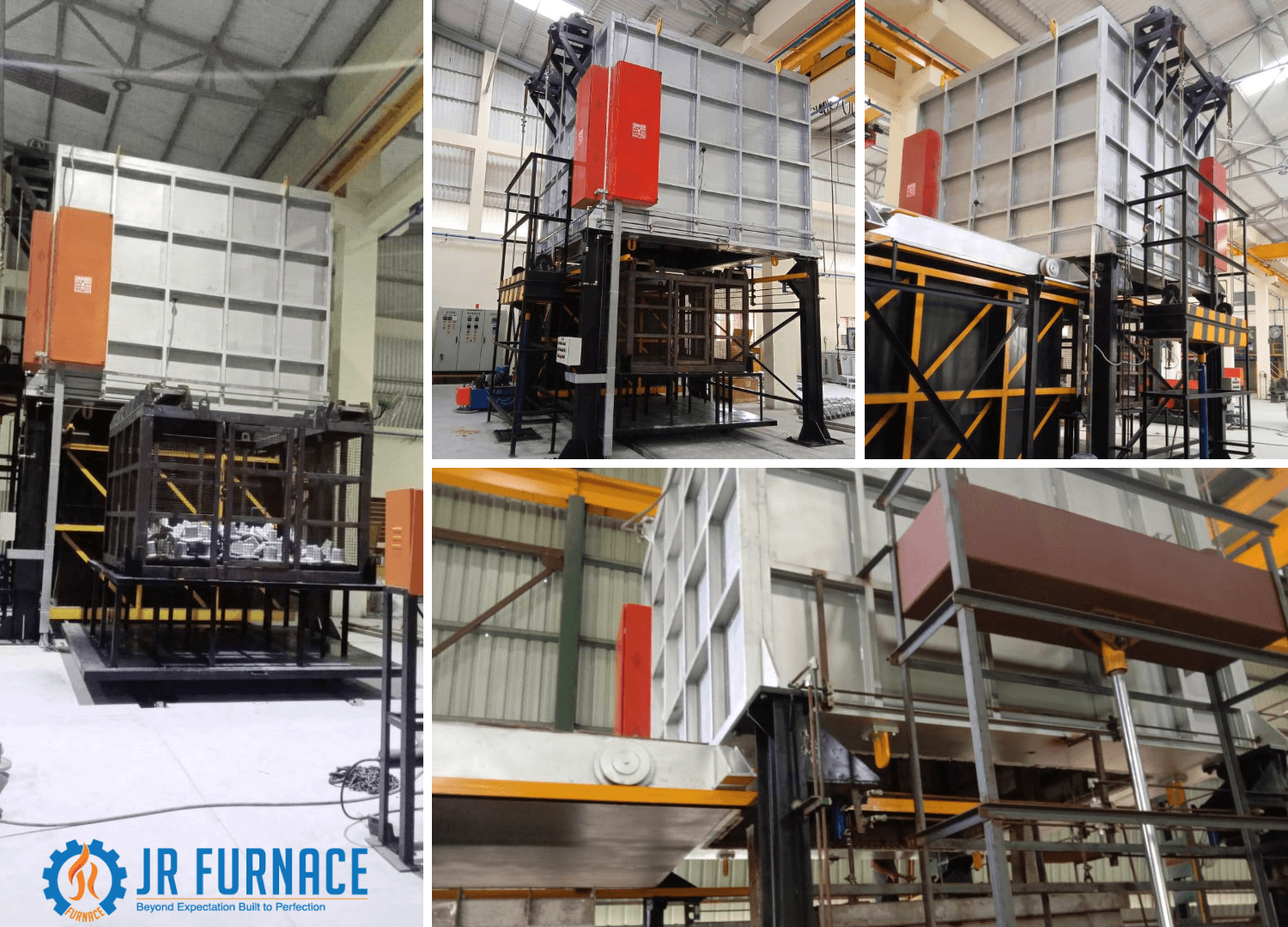

Drop Bottom furnaces are effectively used for the solution heat treatment of aluminum like aluminum extrusions, sheet metal, castings, forgings and other parts in a batch configuration.

The combination of the main features like customized air distribution furnace system, quick door opening, Door opening/closing by Pneumatic mechanism, Basket lifting / Lowering Winching Mechanism, Charge loading and Unloading Motorised Trolley, Ageing Oven and quench tank with required agitation makes this industrial furnace as the best equipment for aluminum and aerospace industries. Quenching delay seconds will be achieved in 7 to 10 sec.

JR Furnace Drop Bottom Quench Furnace are extremely durable, highly reliable, and designed to meet the AMS 2750, CQI-9 and pyrometric requirements for the furnace. Our drop bottom furnaces will serve the industries like Automotive, Aerospace, Die Casting, Forgings etc.

Our furnaces are designed for proper temperature rise when quenching. The Quench system specifically designed custom depending on the product in order to provide the excellent results.

It is designed to comply with AMS 2750E, with temperature tolerance capacity up to class 1 if necessary. It can be heated electrically with low density heating elements.

FEATURES

JR Furnace drop bottom furnaces features are as follows:

- Full automation

- Heavy duty construction

- High volume air flow provides excellent uniformity and heating rates

- Maintenance free door gasket & interior

- Meets Aerospace and CQI-9 norms

- Quick door opening system

- Clamping door seal to prevent air leakage

- Quench delay time of parts 7 to 10 seconds, automatic quench;

- PLC with SCADA based controls

- No pits required

- High capacity re-circulation fans

- Many different control / recording options available

- Temperature uniformity for consistent results

PROCEDURE

The procedure for a drop bottom furnace, loads the product in baskets or on a grid, under the oven. The load is attached to a lift mechanism automatically and lifted into the chamber through the doors located on the bottom of the equipment.

When the doors close the heat treatment process will begin. After the set process time, the doors open, and the load will be lowered rapidly.

For More Information about Industrial furnaces and ovens

Get in touch with us : Email – [email protected]